Utilising the digital implant workflow

Featured Products Promotional FeaturesPosted by: Dental Design 22nd September 2020

Digital has long been heralded as the future of dentistry and now it is very much our present. Even for practices not yet utilising a fully digital workflow, at least some part of the treatment journey will likely involve some technology designed to streamline, simplify and enhance the process.

In implantology, digital solutions have become integral to quality treatment. CBCT imaging is important for comprehensive assessments in challenging cases, digital software ensures meticulous treatment planning and intraoral scanning affords accurate impressions for predictable restoration. Whether clinicians use all these solutions or just some, the benefits of digital support include fewer complications or unexpected challenges, greater protection from potential medicolegal claims and improved patient satisfaction.

The latter advantage comes from patients’ appreciation for increased comfort, reduced time in the chair and more efficient treatment. Plus, they often have a better understanding of the procedure and therefore give more informed consent thanks to digital communication tools and treatment outcome simulations.

To maximise on these and many more benefits when providing implants, clinicians need to use implant systems and concepts that are not only proven to be safe, effective and long-lasting, but that also support the digital workflow.

Fully supported digital workflow

TRI® Dental Implant Solutions – a leading Swiss implant provider – offers a comprehensive but easy-to-use portfolio of products designed to optimise aesthetics, efficiency and economics. The company’s ethos is all about encouraging predictable osseointegration, immediate stability, a strong connection and natural-looking aesthetics, providing a long-lasting solution for a wide range of patients.

TRI® Dental Implant Solutions – a leading Swiss implant provider – offers a comprehensive but easy-to-use portfolio of products designed to optimise aesthetics, efficiency and economics. The company’s ethos is all about encouraging predictable osseointegration, immediate stability, a strong connection and natural-looking aesthetics, providing a long-lasting solution for a wide range of patients.

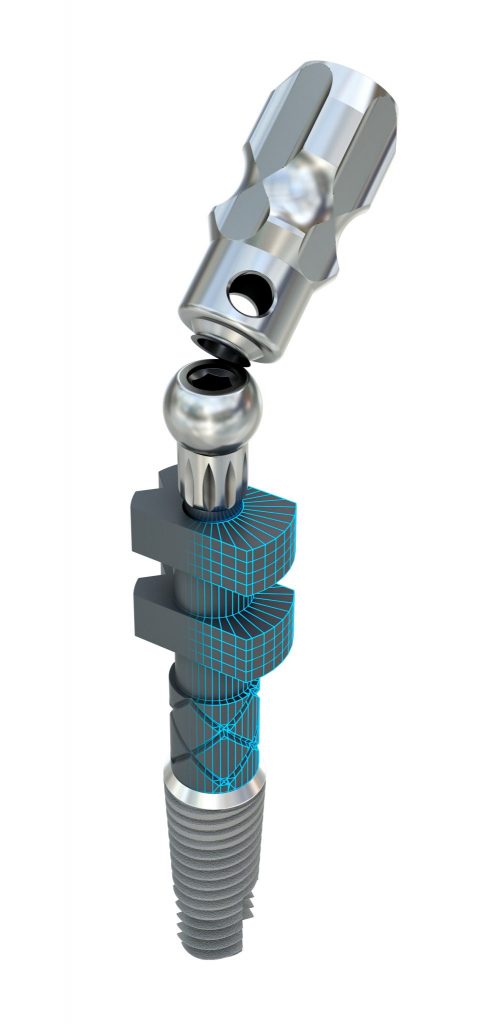

The sophisticated TRI® BoneAdapt Technology of TRI® implants maximises primary stability to support immediate placement and loading protocols for optimal patient satisfaction. The implants are designed to encourage bone adaptation while minimising stress and cortical load. A unique soft tissue interface and range of innovative prosthetic components deliver a consistent emergence profile for outstanding gingival aesthetics as well.

The patented 3D-Touch Open-Tray Impression Post has proven particularly popular over the past year as an intra- and extra-oral scanbody that can be used for both analogue and digital impression methods. The narrow component is ideal for the smallest of spaces and it is connected to the implant without a screwdriver, making it easy to use.

Designed specifically for the digital workflow, the TRI® Digital Implant is the world’s first implant to be created specifically for this type of manufacturing. It simplifies the planning process by eliminating the need for an abutment and cementation, enabling the restoration to be designed directly on the implant. TRI® most recently developed an entire product line specifically optimised for the fully digital workflow – the Matrix®. The 100% screw-retained solution optimises the digital process for an outstanding clinical outcome. Find out more by signing up on the website.

In addition, the leading Swiss supplier supports its customers across the globe with first-class education and training. An extensive library of online tutorials, webinars and training courses is available online, providing a wealth of information and practical advice to help clinicians fully utilise all the potential benefits of the TRI® Dental Implant system. Plus, the company supports other training opportunities by providing its products for delegates to learn with, including those held at the Centre of Oral-Maxillofacial and Dental Implant Reconstruction in Manchester, with Professor Cemal Ucer, Specialist Oral Surgeon.

PG Cert in Implant Dentistry

Delivered through Ucer Education, the training teaches both the practical and theoretical elements of implant placement and restoration. While both analogue and digital techniques are covered to give delegates a solid foundation of knowledge and skill, the course makes use of the cutting-edge facilities at the ICE Postgraduate Dental Institute in Manchester. These include an advanced diagnostic centre with the complete digital workflow including a Morita CBCT machine, Trios and Cerec intraoral scanners, 3D printers and the latest digital treatment planning software. There are also interactive lecture rooms and webinar capabilities to enable delegates to watch live-streamed surgical procedures from the in-house surgeries.

The 12-month, blended learning programme is ideal for those new to the field or clinicians with some experience who wish to consolidate and develop their existing skills. It concludes in a level 7 award by EduQual to provide a formally-recognised qualification that endorses the quality of the training delivered. What’s more, support and mentorship is available throughout the course and beyond personally from Professor Ucer and members of his world-class teaching colleagues, ensuring all delegates apply their new skills in practice safely and effectively.

Maximise digital potential

Dental implantology is a rapidly developing and exciting field of dentistry. If you’re interested in capitalising on the opportunities, consider utilising the benefits of a partial or complete digital workflow with industry-leading products and world-class training.

For more information on the PG Cert in Implant Dentistry from Ucer Education – supported by Geistlich, Megagen, Neoss, TRI Implants and General Medical – please visit www.ucer.education or call Prof Ucer on 0161 237 1842

Email ucer@oral-implants.com

For further details about the TRI® implant portfolio, please visit www.tri.swiss or email info@tri-implants.swiss